Time:2025-02-17

Jiugang Group Hongsheng Electric Heating Company Aluminum Electric Branch

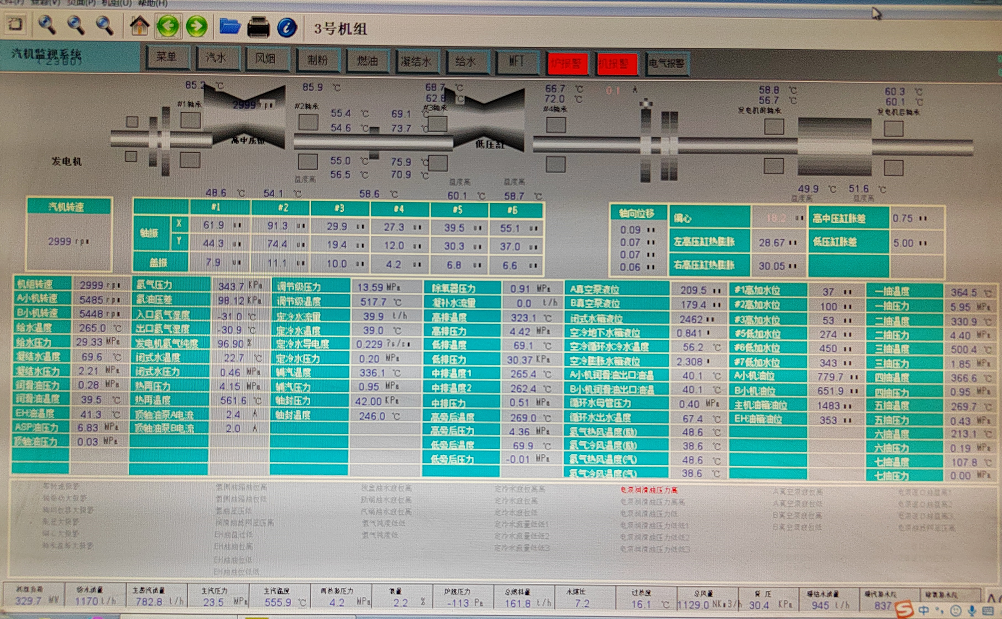

Jiugang Group Hongsheng Electric Heating Company Aluminum Power Branch installed a total of 4 350MW units, with steam turbine equipment manufactured by Dongfang Turbine Co., Ltd. The unit model is CJK350/285-24.2/0.45/66/566, and the unit type is supercritical, one intermediate reheating, single shaft, two cylinder two exhaust, indirect air-cooled extraction condensing steam turbine.

Main Content

Responsible for the A-level maintenance of the turbine body and auxiliary equipment of Unit # 3 of the Aluminum Power Branch, and cooperating in the handling of main equipment problems and hidden dangers discovered during the A-level maintenance.

Responsible for cylinder opening maintenance of A and B steam driven feedwater pump turbines, and cooperating with the maintenance of steam seals for A and B steam driven feedwater pump turbines of Unit # 3 of Aluminum Power Company.

Responsible for the A-level maintenance of Unit 3 generator in Aluminum Power Branch, and cooperating in handling the main equipment problems and hidden dangers discovered during the A-level maintenance.

Responsible for the thermal engineering related work of the # 3 unit steam turbine, generator, and ancillary equipment of the Aluminum Power Branch, as well as the calibration work of the large and small machine shaft system detection probe tachometer, sulfur hexafluoride oil pressure relay, etc.

construction preparation

According to the epidemic prevention and control requirements of Jiayuguan, all visitors to Jiayuguan must undergo a three-day two check epidemic prevention screening. After the screening, the personnel must undergo home quarantine observation and cannot live in gatherings; The company initiated the project in advance and arranged for management personnel to prepare locally, providing a good living environment for future personnel upon arrival at Jiayuguan.

After the personnel arrived at Jiayuguan, they promptly communicated with the site, and containers, tools, isolation measures, and other materials were brought into the factory accordingly. After the personnel entered the site, on-site arrangements and other work were immediately carried out; The project has sufficient material preparation, reasonable technical connection, and appropriate resource utilization. The on-site civilized construction layout is standardized, the placement of tools and spare parts is orderly, and the work is carried out in an orderly manner, which has received unanimous praise from the owner.

Construction process

The contract for the maintenance period is 45 days. Due to the tight load of the owner's self owned power plant, the construction period is required to be completed within 42 days. The company strictly controls the construction period internally and strives to complete it within 40 days;

During the construction process, due to the temporary addition of high-pressure cylinder research for the steam turbine and replacement of wire rods for the generator, the schedule was once again tightened. The project management personnel adopted on-site command and promptly negotiated with the owner's management personnel to rearrange the construction operation sequence. After optimization, the low-pressure inner cylinder was first fastened, then the generator rotor was threaded back, and finally the low-pressure outer cylinder was fastened. Finally, the high-pressure cylinder was centrally fastened and other subsequent work was carried out.

In the context of short construction period and heavy tasks, in order to achieve project goals, the project department fully utilized the advantages of each team, worked overtime, and relied on rich construction experience to successfully complete the project, which was effectively guaranteed.

Project results

With excellent professional skills, reasonable personnel and process adjustments, and flexible response to factors such as increased project volume, the maintenance project was completed within 40 days with the joint efforts of all personnel in the project department, and achieved good results of one-time start-up and grid connection success.

After starting up, the vibration and temperature of the steam turbine are at excellent standards, and the operating data of each auxiliary equipment is excellent. There is no leakage or seepage in the auxiliary equipment, valves, pipelines, oil systems, etc; This maintenance has no safety accidents, no equipment quality accidents, and excellent schedule control. The overall evaluation has reached a first-class level, creating a good reputation for the company and laying a solid foundation for future cooperation in the market.

Tel

TOP